From the Lab, Resources for Roasters

Monday, June 7, 2021

Improving the Way We Store Coffee

We’re always striving for better solutions that save money, reduce our environmental impact and bring you great coffee at better prices. Recently, our quality control (QC) team in Asia Pacific undertook a 9-month test to determine the best way to maintain coffee quality while reducing our environmental footprint. To do this, they evaluated the difference between warehouse storage with and without air conditioning (AC).

Key Factors in Storage

There are three factors that influence coffee quality during transportation and storage: oxygen, temperature and humidity.

Oxygen: Oxygen has such a detrimental effect on coffee that some articles refer to it as a “contaminant.” As coffee interacts with oxygen, it causes the flavor molecules to oxidize and even turn rancid, causing off-flavours and a flat taste.

Temperature: The ideal temperature range for coffee storage is 20 to 25 degrees Celsius (68 to 77 degrees Fahrenheit). Temperature impacts coffee by modifying water activity inside the bean. Changes in the energy status of the water molecules in coffee can affect flavor and freshness. In some conditions, vast fluctuations in temperatures can cause condensation inside a bag of coffee, which can ruin coffee.

Humidity: Similarly, environmental humidity, the measure of how much moisture is in the air, can affect coffee by traveling in and out of bags of coffee. Too much humidity can also cause mold or mildew growth, ideal relative humidity (RH) is 60%. (2)

The Experiment

The initial reasons coffee was stored in AC storage were to keep humidity and temperature constant. When they set out to evaluate the impact of AC on warehoused coffees, the QC team wanted to retest this initial hypothesis and determine how cupping quality varies between AC and non-AC storage.

Warehouse temperature

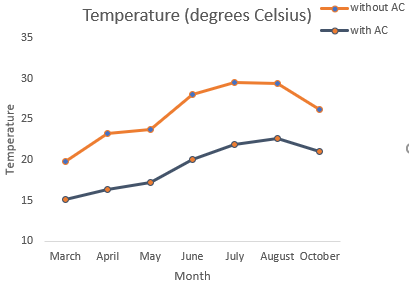

To begin, the team selected a range of coffee grades – both specialty and commercial – to store in 2 warehouses in Tsuen Wan, Hong Kong, one with AC and one without, for 9 months. All of these coffees were stored in hermetic packaging. They used an LCD Digital Temperature & Humidity Meter HTC-1 H596 thermometer to record temperature and relative humidity (RH) daily.

Samples were drawn at the end of each month over the course of 9 months. They drew samples from each bag and checked moisture content, water activity and density. Then, the Hong Kong QC used SCAA cupping protocols to evaluate cup quality. Since the purpose was to evaluate quality, not consistency, only 2 cups were used to cup the coffee. All other SCAA protocols were observed.

The Results

Their results were striking: While humidity and temperature in the non-AC warehouse were vastly different from the suggested storage conditions and from the AC warehouse, the team found no significant difference in cupping scores.

Cupping notes of AC coffees

Cupping notes of non-AC coffees

The AC conditions did not delay past crop taste. In both conditions, fading characteristics begin to show after 9 to 12 months in storage. In fact, some coffees in the non-AC warehouse had more desirable characteristics after a 9 to 12-month storage period than those stored in the AC warehouse.

Two-way ANOVA analysis, a statistical method commonly used in research to measure the difference between groups, showed no significant differences in water activity, density or moisture content between 2 storage conditions.

Packaging Matters

Previous studies have found that cold storage can prolong cup quality. However, there are several key differences in conditions between previous studies and our QC team’s study. Cold storage studies typically study conditions that are near-freezing. The different between our AC and non-AC warehouses was only 8 degrees and not near freezing, suggesting that the different between AC and non-AC storage was not enough to impact quality overtime.

Additionally, these studies were conducted on coffees that were stored in packaging that was not hermetically sealed. Several studies have found that, rather than storage conditions, the best indicator of a coffee’s longevity was packaging. In those studies, vacuum packaging – removing air and creating a hermetic seal – proved to be the best way to preserve coffee quality. The bags used for hermetic sealing are impervious to moisture.

In the study our QC team conducted, coffees stored in hermetic packaging maintained desirable flavors including chocolate, vanilla, citrus and red fruits (1). Conversely, studies found that the coffee stored in the jute sacks displayed more undesirable characteristics such as papery and jute (1). These results are most likely due to the fact that coffee stored in non-hermetically sealed bags were exposed to oxygen, which caused the flavor-producing oils to oxidize and lose their flavors.

Reducing Our Footprint

The results from this study provided clear answer: we can reduce our environmental footprint while maintaining coffee quality. We’ve seen that AC in warehouse storage is not a major factor of coffee quality overtime. By moving coffees to a non-AC storage facility, we can reduce overall storage costs, minimize our environmental footprint and still deliver excellent quality coffees to our clients.

References

1. Borém, F. M., Ribeiro, F. C., Figueiredo, L. P., Giomo, G. S., Fortunato, V. A., & Isquierdo, E. P. (2013). Evaluation of the sensory and color quality of coffee beans stored in hermetic packaging. Journal of Stored Products Research, 52, 1-6. doi:10.1016/j.jspr.2012.08.004

2. Lopes, D. D., & Neto, A. J. (2020). Modelling the dry matter loss of coffee beans under different storage conditions. Journal of Stored Products Research, 88, 101669. doi:10.1016/j.jspr.2020.101669/